Sumitron gives you the best quality Rework Stations and equipment with brilliant features and performance with the least maintenance and long life. It is really important to select the right brand, just like HAKKO, which provides High-quality products at an economic price. A reliable Brand is the key factor before buying a Rework station.Sumitron gives you a high-quality Hakko Fr-810 B turbine-powered Rework Station which best for the required job. For SMT and PTH work vacuum pump plays a major role.Always look for a versatile set of bits along with a Rework station for heavy-duty applications.At Sumitron, we have HAKKO FR-702 four ports Rework Station that can be the best choice for this job, also at a reasonable price. So always invest in a work station that includes de-soldering iron with handpiece stand. For the Desoldering process, a Desoldering Iron is necessary.There are few tips that can help you while buying a good Rework Station Get the best deals on Industrial Soldering & Rework Stations when you shop the largest online selection at. The products range from economic to highly expensive according to the different levels of work situations. While a regular hot-air solder rework station could cost more than 100, a common heat gun available from most home improvement stores should cost no more than 50. There is a number of manufacturers for different products available in the market. A common heat gun is an inexpensive way to reflow, or reattach, electronic components that have been soldered together. For more accuracy go for Digital in nature.It should be ESD (Electrostatic Discharge) safe.FeaturesĪll the Rework stations whether it is dual-port or 3-port, the must-have features are InfraRed soldering also prevents components from mechanical damage and overheating. On the other hand, IR (Infra-Red) Soldering stations are used in the reworking complex elements. Hot-air Rework Station is good for removing components from PCB, also for resoldering new components. Using a good Rework station for doing simple repairing tasks to reworking SMT (Surface Mount Technology) boards or ICs, these stations are easy to use and can be useful for technicians, hobbyists, or design engineers. To do the process we require appropriate tools and expertise just like for Hot air Station for heating and melting solder. Replacement of electronic parts (micro).Poor soldering joints due to Thermal cycling.Broken components due to physical stress or any other reason.Rework can be required due to any these of defects like Rework Station- How Rework Station Works?Ī Rework Station is a place on a workbench for repairing defects in an electronic PCB (Printed Circuit Board). Components, Connectors & Cable Management Solutions.Solder Paste Mixer / Centrifuge Machine.PCB Chemicals & Thermal Management Systems.Nitto Seiko Automated Screwing Solutions.Texwipe Cleanroom Products for Pharmaceutical Industry.Tsutsumi Automatic Soldering Equipments.

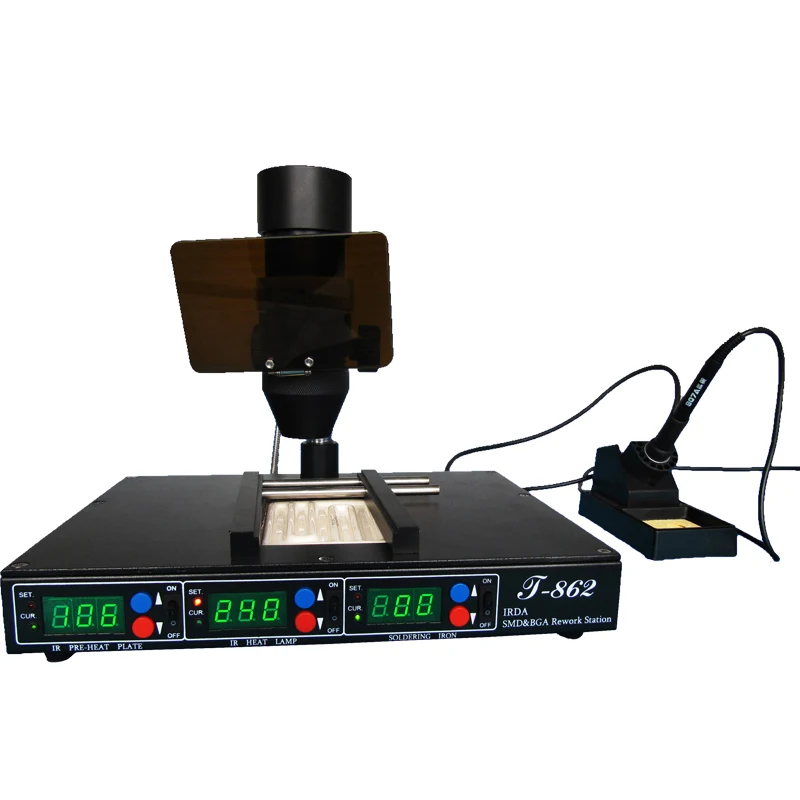

The settings can be blocked by means of a password.

Moreover, this device has an automatic cooling system, which allows for an extended service life of the heating element and the holder. The Quick 861DW ESD uses a magnetic switch, which immediately activates the sleep mode when the handle is placed in the holder.

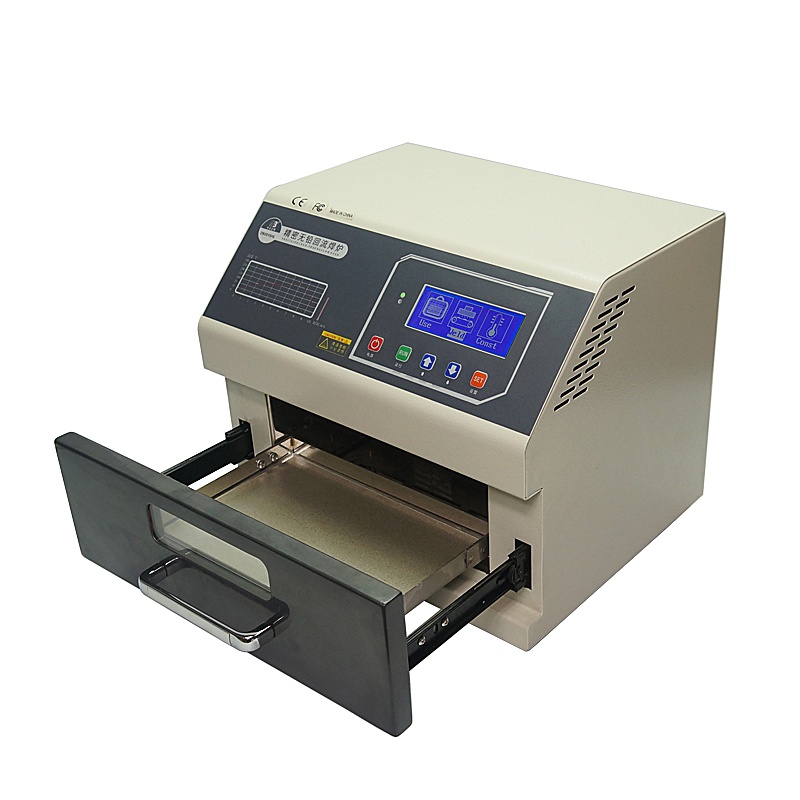

The 861DW ESD has three channels where the temperature and the amount of airflow can be set and these settings can be memorized by the device. Due to the high power and a ceramic heating element, rapid heating to the desired temperature is possible. Furthermore, the Quick 861DW is also suitable for drying, removing paint, melting, heating and disinfecting surfaces. It includes fast heated plate ramping, and a rapid single wafer processing capability of > 20☌/second. This device is designed for soldering SMD components such as SOIC, QFP, PLCC, CHIP and BGA. The Solder Reflow Station is ideal for R&D, process development as well for low to high volume production. The Quick 861DW ESD is an inexpensive hot air station with a high power of 1000 watt and it has a maximum airflow of 120 litres per minute.

0 kommentar(er)

0 kommentar(er)